We offer high-quality raw materials for the production of refractory materials based on aluminum and magnesium. Verified suppliers, strictly controlled quality, multimodal transportation of raw materials, and long-term international business experience are a guarantee of high professionalism and sustainability. We consider these as the main pillars of building strong business relationships, which continuously drive us and our partners forward.

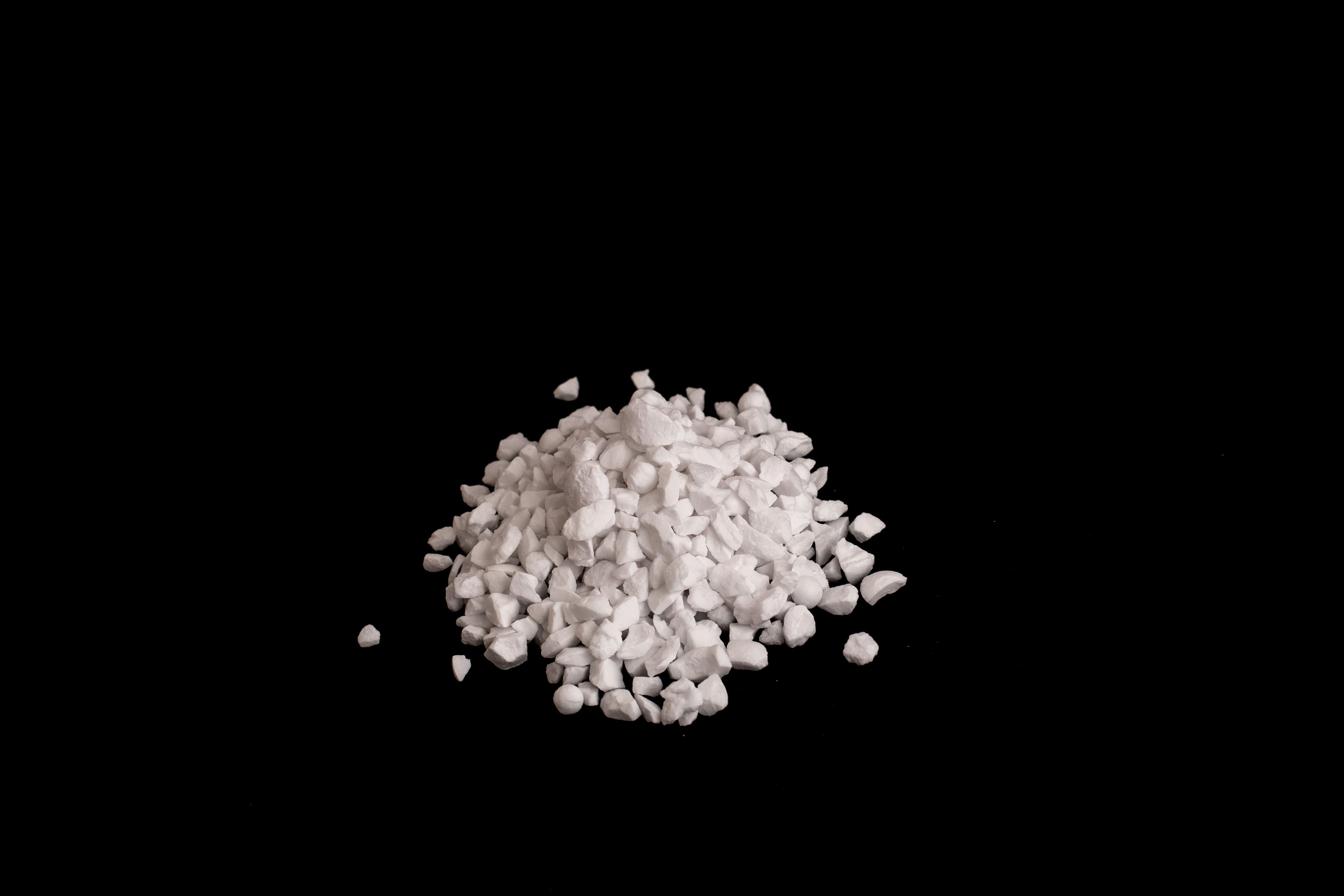

Contact UsWhite Fused Alumina (WFA) is an important raw material for advanced refractories and

abrasives. WFA is widely used raw material in refractories, ceramics, grinding wheels,

sandpaper, blasting media, metal preparation, laminates, coatings, lapping, polishing,

grinding and many of other applications.

Available fractions

0-1mm, 1-3 mm, 3-6 mm, 5-8 mm, powder, or according customers requirements.

Packaging:

Bulk, big bags

Properties:

| Color | White |

|---|---|

| Hardness (Mohs) | 9 |

| Bulk density (g/cm³) | 3,5 – 3,7 |

| Melting point (°C) | 2250 |

| Maximum service temperature (°C) | 1900 |

| Al₂O³ (%) | ≥99,2 |

| Fe₂O³ (%) | ≤0,1 |

| Na₂O (%) | ≤0,4 |

| SiO₂ (%) | ≤0,1 |

Tabular Alumina is a pure sintered alpha-alumina material that has been fully densified by rapid-sintering without the use of sintering aids at temperatures in excess of 1800 °C. Tabular Alumina has characteristc large and well developed hexagonal tablet shaped alpha-alumina crystals of up to 200 μm length.

Available fractions

0-0,05 mm, 0,5-1 mm, 1-3 mm, 3-6 mm, 5-8 mm, powder 180 mesh, 200 mesh or according customers requirements.

Packaging:

Bulk, big bags

Applications:

Tabular Alumina is good choice as aggregates of unshaped and shaped high performance refractories. It is used in a variety of industries such as steel, foundry, cement,

petrochemical, ceramic and waste incineration. Other common applications include its

use in electrical insulators, kiln furnace and as a catalyst support. Ground Tabular is an

excellent product to be used as a filler in epoxy or resin systems where high dielectric

strength, thermal conductivity or abrasion resistance are desired.

| Color | White |

|---|---|

| Apparent porosity (%) | ≤5 |

| Bulk density (g/cm³) | ≥3,5 |

| Melting point (°C) | 2250 |

| Maximum service temperature (°C) | 1900 |

| Al₂O³ (%) | ≥99,2 |

| Fe₂O³ (%) | ≤0,04 |

| Na₂O (%) | ≤0,35 |

| SiO₂ (%) | ≤0,1 |

| K₂O (%) | ≤0,01 |

Brown Fused Alumina is made of high-quality bauxite and refined in electric arc furnace

at more than 2000 °C. Thanks to its high purity, good crystalization, strong fluidity, low

linear expansion coeNicient and great corosson resistance, brown fused alumina is wide

used as raw material of refractory product.

Available fractions

0-1 mm, 1-3 mm, 3-6 mm, 5-8 mm, powder according to customers requirements.

Packaging:

Bulk, big bags

Applications:

Mainly used for abrasion and high temperature resistant, inoxidizable aaggregate and

filling of shaped and monolithic refractories in steel metalurgy, various industrial ovens,

electric furnace etc...

| Color | Brown |

|---|---|

| Apparent porosity (%) | ≤5 |

| Specific gravity (g/cm³) | 3,9 – 4,1 |

| Melting point (°C) | >1850 |

| Maximum service temperature (°C) | 1600 |

| Al₂O³ (%) | ≥95 (granular) ≥94,5 (powder) |

| Fe₂O³ (%) | ≤0,03 (granular) ≤0,5 (powder) |

| TiO₂ (%) | ≤3 (granular) ≤3,5 (powder) |

| SiO₂ (%) | ≤1 (granular) ≤1 (powder) |

Bauxite is one of the principal ore of aluminium. Bauxite contains hydrous aluminium oxides and aluminium hydroxides, formed through the laterization of aluminous rocks in

tropical and subtropical areas. Bauxite is obtained by calcining (heating superior grade bauxite at high temperature ranges fromm 850 °C to 1600 °C). In this way moisture could be removed to increase the alumina content.

Available fractions

0-1 mm, 1-3 mm, 3-6 mm, 5-8 mm, 16-30 mesh, 30-60 mesh, 120 mesh, 200 mesh, 325

mesh or as customers requirements.

Packaging:

Bulk, big bags

Applications:

| Item | SNR90 | SNR88 | SNR86 | SNR85 |

|---|---|---|---|---|

| Bulk density (g/cm³) | 3,3 | 3,25 | 3,2 | 3,1 |

| Moisture (≤%) | 0,3 | 0,3 | 0,3 | 0,4 |

| Al₂O³ (%) | 90 | 88 | 86 | 85 |

| Fe₂O³ (≥%) | 1,6 | 1,6 | 1,8 | 2,0 |

| TiO₂ (≤%) | 4,0 | 4,0 | 4,0 | 4,0 |

| CaO+ MgO (≤%) | 0,4 | 0,4 | 0,4 | 0,4 |

| K₂O + Na₂O (≤%) | 0,4 | 0,4 | 0,4 | 0,4 |

Calcined Alumina is made from industrial aluminium hydroxide or industrial alumina, i tis

generally used to produce slide gate sets, submerged entry nozzles, ladle shrouds,

corundum bricks etc. It could also be used together with reactive alumina in monolithic

refractories to increase liquidity, decrease water addition and porosity, increase strength

and get lower linear change.

Reactive a - Alumina micro powder is widely used ot produce refractory castable for steel

ladle, castable for iron flow through, purge plug, well block, corundum self-flow refractory

castable, gunning repairing mass, etc.

| Typical value | CL-800SG | BM-9FG | BM+1 |

|---|---|---|---|

| Na₂O (%) | 0,06 | 0,12 | 0,04 |

| Fe₂O³ (≥%) | 0,02 | 0,04 | 0,04 |

| MgO (≤%) | 0,01 | 0,02 | 0,01 |

| SiO₂ (≤%) | 0,04 | 0,06 | 0,05 |

| CaO (≤%) | 0,02 | 0,02 | 0,02 |

| Specific surface are

BET (m₂/g) |

0,85 | 0,93 | 1,28 |

| D50 Malvern (μm) | 4,8 | 5,2 | 3,7 |

| D90 Malvern (μm) | 11,3 | 22,7 | 9,2 |

| Al₂O₃ (%) | ≥99,2 |

| SiO₂ (%) | ≤0,10 |

| Fe₂O₃ (%) | ≤0,10 |

| Na₂O (%) | ≤0,50 |

| D50 (μm) | 3 ~ 6 |

| Položka | Alumina Monomodal | Alumina Biomodal |

| Al₂O₃ (%) | ≥99,4 | ≥99,4 |

| SiO₂ (%) | ≤0,10 | ≤0,10 |

| Fe₂O₃ (%) | ≤0,10 | ≤0,10 |

| Na₂O (%) | ≤0,15 | ≤0,10 |

| D50 (μm) | 1 ~ 3 | 1 ~ 4 |

Dear Burned Magnesite is made from selected natural magnesite. It is produced by mine

selecting, purifying and calcinating in shaft-kiln. High temperature performance and high density, easy to rapidly sintered, good thermal stability, strong alkali slag resistance, long service life, etc.

Available fractions

0-0,09 mm, 0-1 mm, 1-3 mm, 3-6 mm, or as customers requirements.

Packaging:

Bulk, big bags

I'm interested

| Item | DBM91 | DBM95 | DBM96 | DBM97 | DBM92 |

|---|---|---|---|---|---|

| Bulk density (g/cm³) | 3,18 | 3,3 | 3,35 | 3,40 | 3,18 |

| Loss of ignition (≤%) | 0,3 | 0,15 | 0,4 | 0,12 | 0,3 |

| MgO (≥%) | 91 | 95 | 96 | 97 | 92 |

| SiO₂ (≤%) | 4,5 | 1,5 | 1,2 | 1,0 | 4,0 |

| CaO (≤%) | 1,6 | 1,6 | 1,6 | 1,0 | 1,6 |

| Fe₂O³ (≥%) | 1,5 | 0,8 | 0,8 | 0,8 | 1,5 |

| Al₂O³ (≤%) | 1,5 | 0,2 | 0,2 | 0,15 | 1,5 |

Fused Magnesite is manufactured by fusion raw magnesite ores which have advantaged

of firm and tight structure, stable chemical properties, high strength etc. This high grade

alkali fused magnesite is mainly used in matellurgy, chemical scientific and research.

Available fractions

0-30 mm, 0-120 mm or as customers requirements.

Packaging:

Bulk, big bags

I'm interested

| Item | FM-96 | FM-97 | FM-97,5 | FM-98 |

|---|---|---|---|---|

| Bulk density (≥g/cm³) | 3,4 | 3,45 | 3,5 | 3,5 |

| Loss of ignition (≤%) | 0,4 | 0,3 | 0,2 | 0,2 |

| MgO (≥%) | 96 | 97 | 97,5 | 98 |

| SiO₂ (≤%) | 1,1 | 0,7 | 0,6 | 0,5 |

| CaO (≤%) | 1,4 | 1,4 | 1,2 | 1,1 |

| Fe₂O³ (≥%) | 1,0 | 0,8 | 0,7 | 0,5 |

We are here for you! Do not hesitate to contact us with any questions or requirements. We are happy to help you find the best solution.

Phone: +421 917 724 176

Phone: +421 917 724 176

Contact for Industrial Solutions: info@pyrometal.sk

Contact for Industrial Solutions: info@pyrometal.sk

Address for Invoice Submission: invoices@pyrometal.sk

Address for Invoice Submission: invoices@pyrometal.sk